-

Bridges

-

Buildings

-

Water infrastructures

-

Energy infrastructures

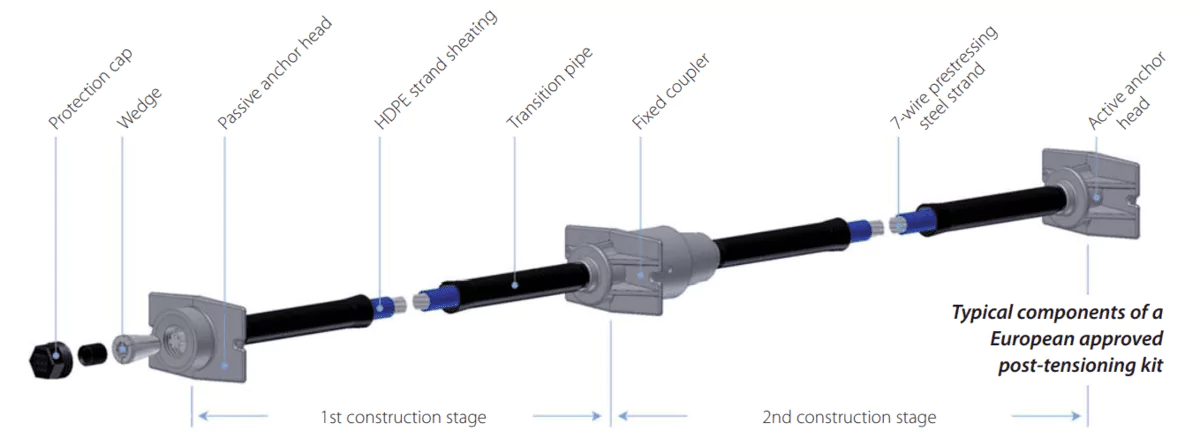

Our Post-tensioning Solutions

For over 80 years, Freyssinet has played a key role in building construction, enhancing structural performance through the use of post-tensioned slab technology. Our expertise and technical know-how contribute to the delivery of increasingly functional, efficient, and durable structures.

All our post-tensioning systems are CE marked, guaranteeing high product performance, rigorous quality control, and advanced installation methods

Post-tensioning Benefits

Post-tensioning enables a broad array of geometric and architectural possibilities, allowing for intricate curves, varying elevations, and extended unsupported spans

Post-tensioning greatly minimises the need for concrete and steel in both the structure and foundation. It also facilitates the swift assembly of precast elements through industrialised methods, ensuring faster and more efficient site progress.

This solution minimises the need for joints, thereby reducing joint maintenance. In tanks, silos, and reservoirs, it greatly reduces the risk of cracked concrete, significantly lowering the risk of corrosion issues.

Post-tensioned structures use fewer construction materials, such as steel reinforcement and concrete, leading to lower greenhouse gas emissions from production and transportation. This typically results in carbon savings of 20 to 30%.

Discover Our Projects

Contact us

You have a question about our solutions or you already have a project in mind? Please fill out the form below and our teams will get back to you shortly.