Freyssinet Australia brings proven expertise in the design, fabrication, installation, monitoring and replacement of bearings. Our integrated approach ensures the right bearing type is selected from the early design phase through to installation, allowing for seamless integration into the structure and optimal on-site performance.

Our Bearing Solutions

Freyssinet Australia offers a wide selection of bearings to suit a variety of structural and movement requirements. Each type is designed to meet specific articulation demands of the structure, with full compliance to Australian and state standards, including AS 5100.4.

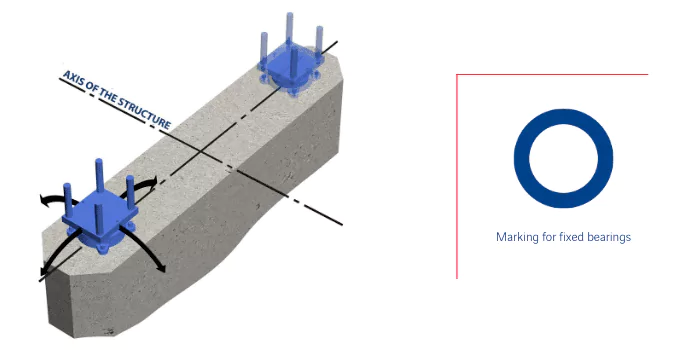

- Fixed – Restricts movement in all directions.

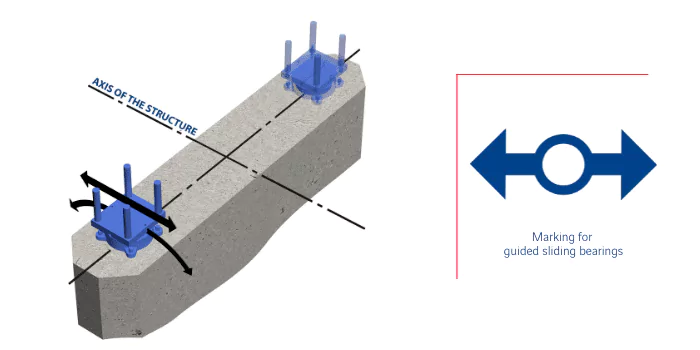

- Guided-Sliding – Allows movement in one direction while restricting it in the other.

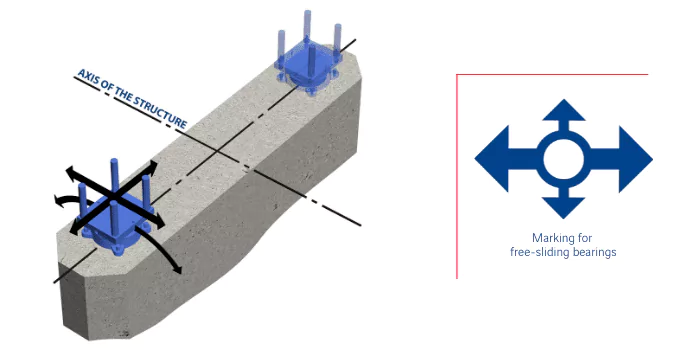

- Free-Sliding – Permits movement in both directions.

All of these are custom designed and manufactured in accordance with project-specific load, displacement and articulation requirements.

- Support vertical loads

- Resist horizontal forces in both longitudinal and transverse directions

- Prevent movement in all directions

- Allow rotation about all axes

- Support vertical loads

- Allow horizontal movement in one direction

- Resist movement and transfer forces in the other horizontal direction

- Accommodate rotational movements

- Support vertical loads

- Allow movement in both horizontal directions

- Do not transfer horizontal forces

- Allow for full rotational movement

Complete Bearing Solutions

Freyssinet Australia offers a comprehensive range of structural bearings using innovative materials and designs. Our end-to-end service ensures each solution is fully tailored, from design and manufacture to installation and long-term maintenance.

To meet complex structural and environmental demands, Freyssinet provides a selection of tailored add-ons for its bearing systems. These may include:

- Components to enhance space efficiency

- Monitoring systems for long-term performance tracking

- Features to streamline installation in challenging conditions

These enhancements improve durability, reduce maintenance costs and extend service life across a wide range of applications including bridges, buildings, transport structures and industrial facilities.

Bearings are critical components in managing movement and transferring loads between structural elements. Exposure to weather, traffic and contaminants can degrade performance over time. Freyssinet delivers expert inspection, maintenance and replacement services to ensure continued safety and functionality.

Our advanced jacking systems and temporary support works enable bearing replacement with minimal disruption to operations or traffic flow.

Commonly used in lighter structures, elastomeric bearings provide a flexible, cost-effective option. They accommodate vertical loads and allow movement and rotation in all directions within defined limits, making them ideal for low-load and moderate-displacement applications.

Tetron pot bearings are designed for high vertical loads and minimal horizontal displacement. A confined elastomeric disc within a steel pot allows rotation while maintaining stiffness and durability. This makes them ideal for bridges and other heavy-duty structures.

Tetron spherical bearings allow for high vertical loads and large rotational movement with minimal resistance. Their spherical design ensures low friction rotation in multiple directions, making them suitable for complex structures requiring both durability and flexibility.

Freyssinet’s Tetron shear keys (SK) and pin keys (PK) are used to control movement and manage large horizontal forces.

- Shear keys restrict displacement in one direction while allowing rotation

- Pin keys fully restrain horizontal movement while permitting rotation

Often used alongside free sliding bearings, these restraint systems ensure the correct articulation and stability required for optimal structural performance.

Discover Our Projects

Contact us

You have a question about our solutions or you already have a project in mind? Please fill out the form below and our teams will get back to you shortly.