- Developed lift methodology from planning stage through to execution

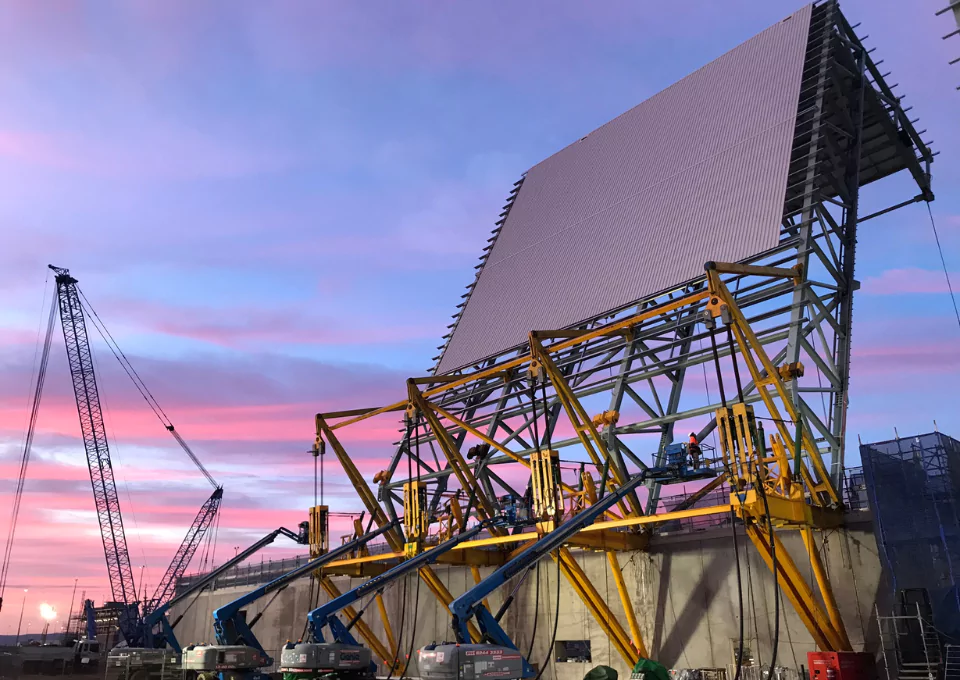

- Designed, supplied, and operated the heavy lifting system in collaboration with Hebetec Engineering

- Successfully executed 14 heavy lifts:

- 10 wall rotations

- 2 roof lifts

- 2 crane beam lifts

- Certified all heavy lifting operations to meet safety and compliance standards

- Delivered alternative wall rotation construction technique to reduce high-risk steel erection

- Enhanced site safety by minimising work at height and reducing wind exposure risk